The first Circular Industry Day, organised by North Sea Port and Smart Delta Resources, took place today, 16 May, in Vlissingen. For the first time, companies, government agencies and research institutions came together to make the circular economy a reality in the region.

The circular economy is high on the agenda for many companies in the North Sea Port as they strive to develop the port sustainably and achieve a carbon-neutral port by 2050. Developing a circular economy requires intensive cooperation. To strengthen this cooperation, North Sea Port and Smart Delta Resources brought together companies, public authorities and research institutions from across the Dutch-Belgian border at the first Circular Industry Day.

50 hectares of cluster space for circular projects in 7 spearhead sectors by 2025

Doing business in a circular way at North Sea Port offers huge opportunities for all sectors. In the circular economy, residues, waste and energy streams become new raw materials. By creating partnerships between companies and optimising material flows, a circular ecosystem is created in which raw materials are reused.

Daan Schalck, CEO, North Sea Port: “The port authority is aiming to provide 150 hectares of cluster space for circular projects by 2025 and to attract at least ten innovative circular activities involving innovative technologies or processes. Those activities must be complementary to the seven spearhead sectors in our Strategic Plan for them to remain future-proof: chemicals, steel, construction materials, energy, automotive, food and feed, and value-added logistics.”

According to the chairs of Smart Delta Resources Netherlands and Flanders, Anton van Beek and Manfred Van Vlierberghe, respectively: “The industries collaborating in Smart Delta Resources are diverse and among the world leaders in innovation. They are companies that manufacture products we use every day. Industry needs to move towards cleaner manufacturing. We want to do that here in the port region. We are keen to adopt a leading role and are committed to demonstrating the essential connection between a circular economy and the energy transition.”

Circular industry activities in the region

Many ports in Europe are working to attract circular projects. But North Sea Port has a head start: old processes, such as those using oil and coal, are already being phased out. North Sea Port is gradually moving towards a circular economy. At the Circular Economy Day, many different circular activities were presented. After all, North Sea Port is already the scene of very intensive cooperation. Here are a few examples:

Sagro turns waste streams into new raw materials and products to create sustainable living environments. Circular demolition has been part of that process for years. They strive to maximise one-to-one reuse, with a reuse rate that stands at an astonishing 98%. The reusable materials in question are utilised in the circular construction market or for future projects.

Neste is committed to accelerating the circular economy. For example, waste and residual streams are stored and pre-processed before being upcycled into high-quality renewable raw materials and fuels in the refineries. Together with Ravago, Neste is planning to construct an industrial plant in Vlissingen to convert non-recyclable plastic waste streams into valuable end products.

Enough has built a plant that utilises bio-refining capacity at Cargill for the production of sustainable proteins. This results in the most sustainable possible source of food proteins. By using their food streams in a circular way, Cargill and Enough are contributing to a more sustainable future.

Near Dow is Valuepark Terneuzen. Valuepark Terneuzen, a joint venture between Dow and North Sea Port, is the perfect location for new initiatives. The space still available is intended to be an incubator for new chemical processes aimed at reusing what are currently residual products and producing circular carbon.

Dow Terneuzen operates 16 chemical plants, including three world-class crackers that make the raw materials for products we use every day. Those crackers can crack anything – by-products of oil and gas, such as naphtha, but also waste and biomaterials. Crackers are the biggest recycling machines available today, and they can help in achieving circular industry.

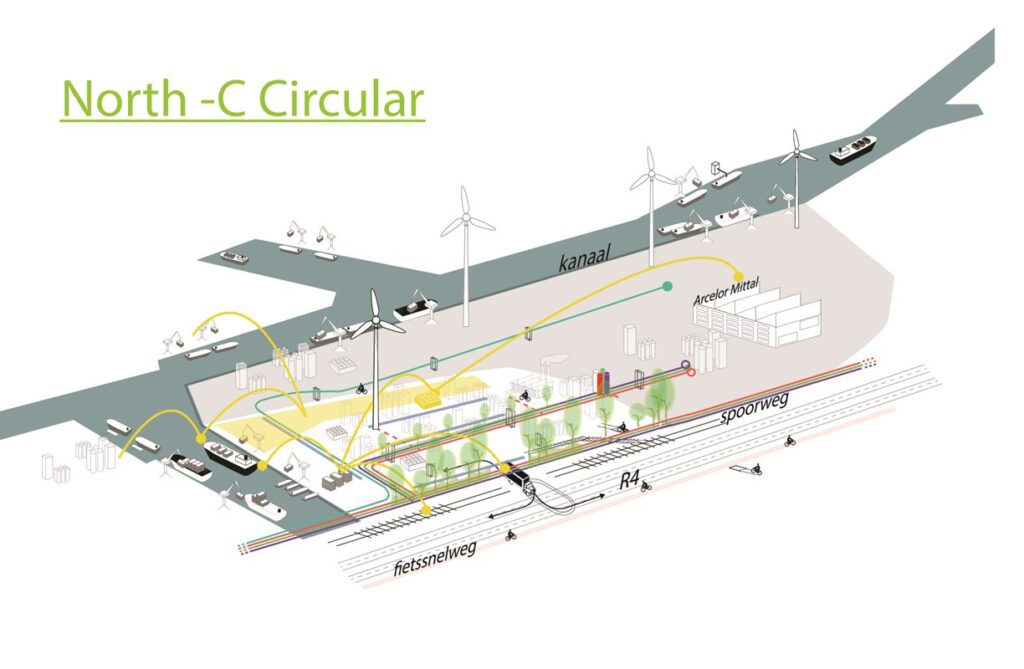

In order to contribute to a climate-neutral port by 2050, North Sea Port and ArcelorMittal are jointly developing the North-C Circular business park. This will strengthen economic activities around reducing ArcelorMittal’s CO2 emissions, the transition from fossil to renewable raw materials, the circular economy and partnerships with regional companies.

Renewi gives used materials new life every day. Of the 14 million tons of waste they process annually, 89% are recycled or used for energy recovery. In this way, Renewi extracts tomorrow’s raw materials from today’s waste and contributes to a more sustainable society.

This post Eerste Circular Industry Day brengt de circulaire industrie in North Sea Port samen – North Sea Port first appeared on the North Sea Port news site on May 16, 2023.

Images credit: North Sea Port