New protein plant Enough at North Sea Port

Waste becoming raw materials: working together to create a fully circular economy is a North Sea Port spearhead. By 2050, they want to stop using fossil fuels, and they support our companies in doing so.

ENOUGH

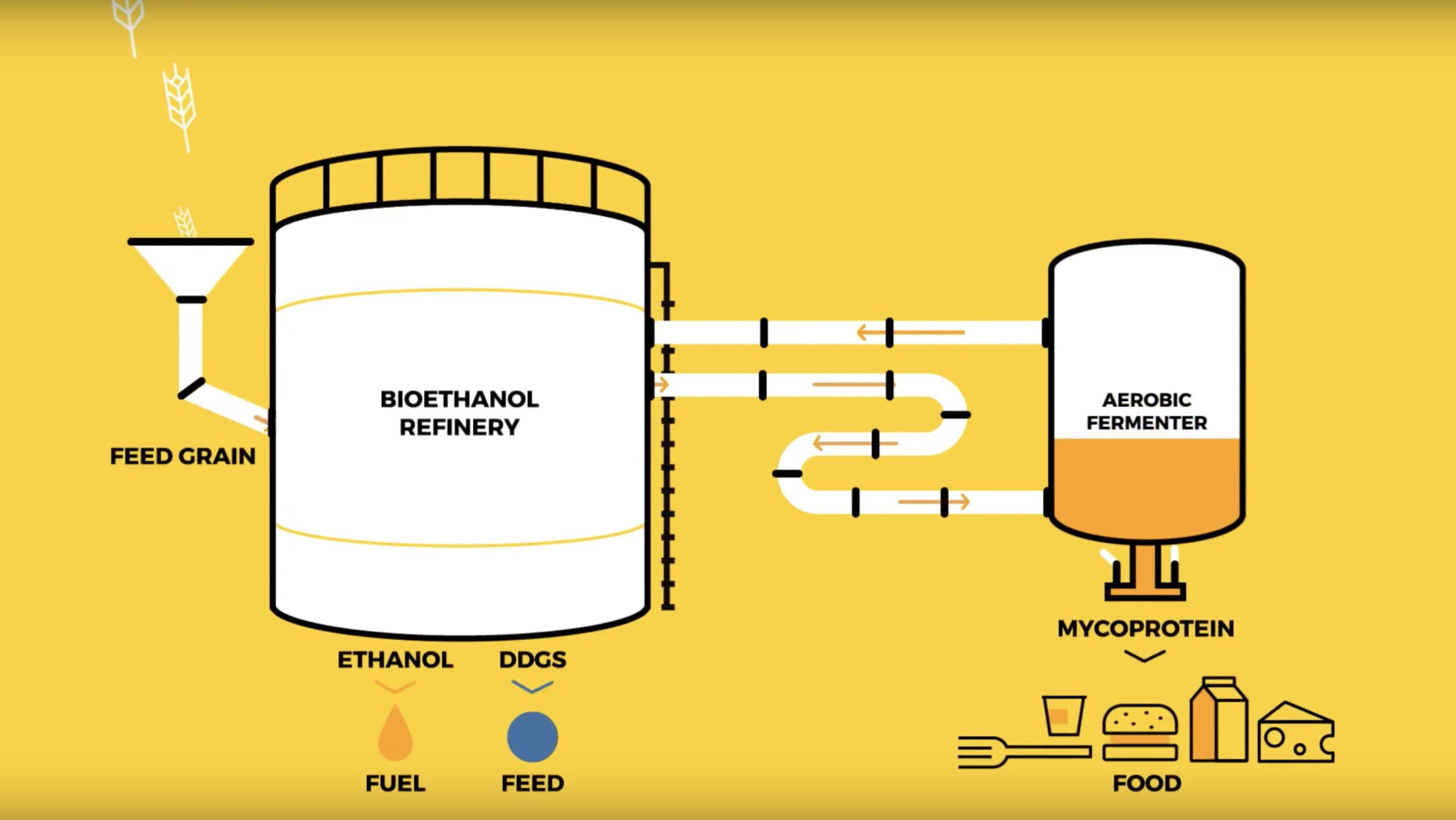

Circular economy today goes far beyond reusing metal from old ships. With the help of the Bio Base Europe Pilot Plant, for example, the port companies in North Sea Port can perfect their processes. This includes Enough, which produces vegetable proteins for meat substitutes. Their raw material comes from neighbors at Cargill, and their unfermented sugars in turn end up at the bioethanol plant next door.

“So we will soon be producing as much protein every four minutes as there is in two cows,” says CEO Jim Laird. “The plant we are now building in the port area could well become the largest protein plant in the world, especially with the market developing so rapidly. We believe our fermentation process is the most sustainable and efficient way to produce protein.”

And they have perfected that process at Bio Base Europe Pilot Plant. Hendrik Waegeman explains how they do it: “The processes that companies develop on a laboratory scale, we scale up to industrial scale. By mimicking the process as it would be applied in a factory, we can start optimizing that process.”

Keep up with the circular economy

“If you want to stay relevant as a company, you simply have to keep up with this circular economy,” concludes Karel Van den Berghe, professor of circular economy at TU Delft. “You have to ensure that materials can be reused longer and more locally. That may come at a cost, but one that pays for itself. You not only create new jobs, you also save the planet with it!”

ENOUGH is a food ingredient company, born from 3F BIO to manufacture and sell ABUNDA mycoprotein as a B2B Ingredient.

This post “Bekijk Onze Haven: North Sea Port zet in op circulaire economie” first appeared on the website of North Sea Port. (September 8, 2022).